Why Modular Manufacturing Matters for Housing Affordability in Pennsylvania

Housing affordability remains one of the most pressing challenges facing communities across Pennsylvania. Demand continues to outpace supply, while rising construction costs, labor shortages, and schedule uncertainty make it harder to deliver new housing efficiently. Addressing this gap requires practical solutions that increase housing supply, improve cost certainty, and support local jobs.

Pennsylvania’s Housing Supply Gap

Director of Engineering, Mike Kirby, discussing modular construction.

Pennsylvania is facing a growing housing shortfall. State-level housing analyses project that the Commonwealth could be nearly 185,000 homes short if construction activity does not increase meaningfully in the coming years. This supply gap places sustained pressure on rents and home prices, particularly in small cities and legacy communities where new housing production has lagged demand.

Increasing housing supply is the only long-term way to stabilize costs. That requires construction methods that can deliver housing faster, more predictably, and at scale.

A Local Example: Studebaker Lofts in Olyphant

This week, we welcomed Pennsylvania State Senator Marty Flynn to our manufacturing facility for a plant tour and discussion focused on housing supply, affordability, and economic development. During the visit, one of the projects moving through our production line was located directly in his district.

That project, Studebaker Lofts, is a 26 unit townhouse-style development in Olyphant, Pennsylvania. The site sits along Hull Avenue and Ash Street, forming an L-shaped layout within the neighborhood. The project name reflects the site’s history, as a Studebaker vehicle repair facility once operated there. A large Studebaker sign discovered on the property is planned to be preserved and mounted at the completed development.

Modular Duplexes with Drive Under Garage

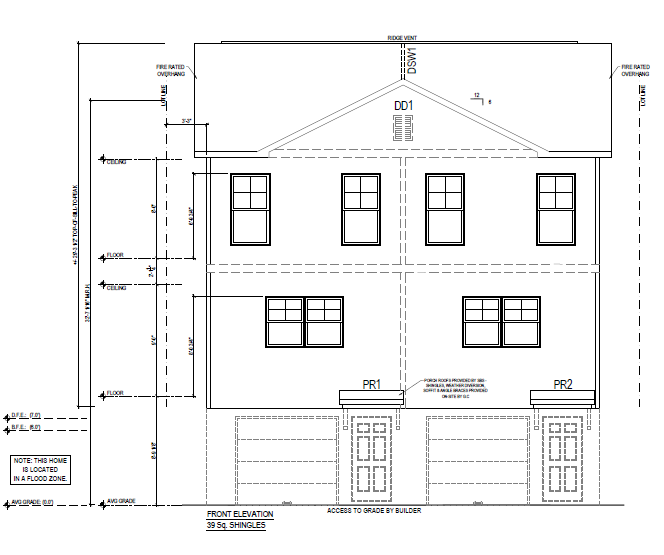

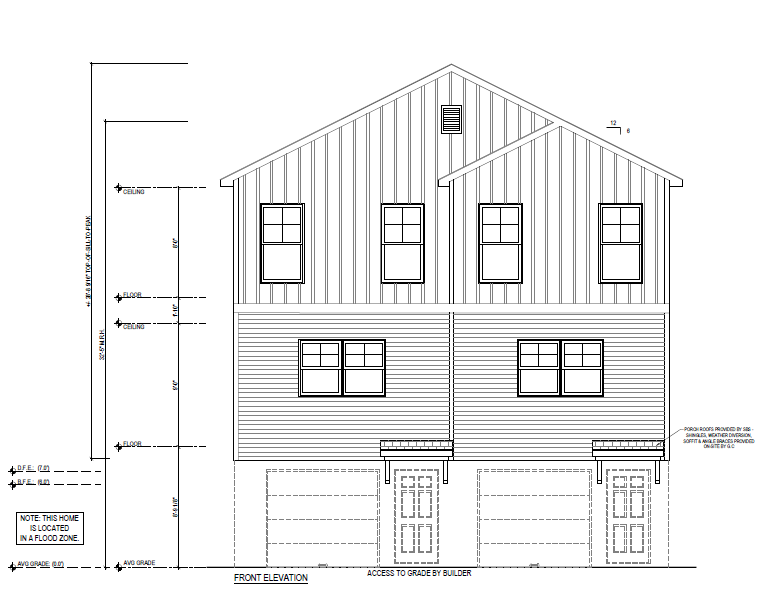

The project consists of 13 duplex buildings, delivering 26 living units in total. Each duplex is constructed from four modular units, resulting in 52 total modules. All modules measure 16 feet by 40 feet and are fabricated in Signature’s controlled factory environment.

The floor plans across the development are consistent, with each side of the duplex featuring a two-story layout with two bedrooms and one and a half bathrooms. Two exterior design variations are used to create visual diversity across the site. One duplex style features a gable roof with the peak facing forward, while the other uses a transverse roof with the peak running left to right. These rooflines are alternated throughout the site to break up repetition and maintain a residential streetscape.

The project is being developed by Dinamico and is scheduled for installation in Q2 of 2026.

Modular Duplexes with front facing on the gable side.

How Modular Construction Accelerates Housing Delivery

Modular construction shifts much of the building process into a controlled manufacturing environment. Homes and apartments are fabricated indoors rather than built entirely on site. This reduces weather delays, improves quality control, and allows multiple phases of construction to occur in parallel.

For projects like Studebaker Lofts, this approach enables faster and more predictable delivery compared to traditional construction. In housing markets facing persistent supply shortages, speed is critical.

Cost Predictability in a Volatile Construction Market

Traditional construction faces growing exposure to labor availability issues (construction labor aging out of job market), material price volatility, and schedule overruns. These risks can disrupt projects and strain budgets, particularly for small and mid-sized housing developments.

Modular manufacturing improves cost predictability by standardizing production, outsourcing labor to the factory, and reducing on site uncertainty. This allows developers to plan more confidently and helps projects move forward without late stage cost escalation.

Manufacturing Jobs and Economic Development in Pennsylvania

Modular construction supports skilled manufacturing jobs that remain in Pennsylvania. Carpenters, electricians, engineers, logistics teams, and project managers all contribute to factory built housing. These roles provide stable employment while supporting a broader regional supply chain.

Housing production and economic development are aligned outcomes. Modular manufacturing allows communities to add housing while strengthening local industry and workforce participation.

A Practical Tool for Addressing Affordability

Modular construction is not a single solution to Pennsylvania’s housing affordability challenge, but it is a proven and scalable tool. It allows communities to add housing faster, manage costs more effectively, while still support local jobs.

Projects like Studebaker Lofts show how factory built construction can deliver real housing in Pennsylvania communities, while respecting local context and site history. Expanding the use of modular construction will be an important part of closing the housing supply gap and improving affordability across the state.

We appreciate Senator Flynn taking the time to tour our facility, engage with our team, and see firsthand how modular manufacturing is supporting housing delivery and economic development in his district and throughout Pennsylvania.